The efficiency and reliability of power plants depend significantly on the performance of their boilers. Boilers in power plant systems play a critical role in generating steam, which drives turbines to produce electricity. Proper water treatment is essential to ensure optimal boiler performance, prevent scaling, and reduce operational costs.

In this blog, we’ll explore the importance of water treatment for boilers in power plant systems, discuss the different types of boilers used, and highlight the best practices for maintaining their efficiency.

Understanding Boilers in Power Plants

A boiler in power plant systems is a device that converts water into steam by applying heat energy. This steam is then used to drive turbines for electricity generation. Boilers are essential for thermal power plants, where coal, gas, or other fuels are burned to produce the necessary heat.

Different Types of Boilers in Power Plants

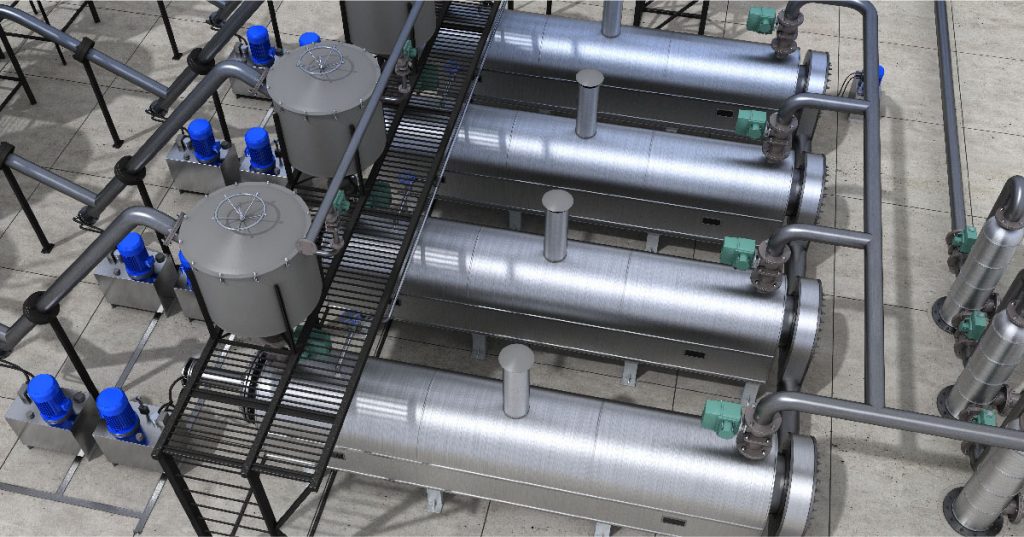

There are various types of boilers in power plants, each designed for specific applications and operating conditions. Understanding these types is crucial to selecting the most suitable boiler for a thermal power plant.

1. Fire-tube Boilers

Fire-tube boilers are compact and widely used for smaller power plants. In these boilers, hot gases produced by combustion pass through tubes surrounded by water, transferring heat to produce steam.

2. Water-Tube Boilers

Water-tube boilers are commonly used in large power plants due to their ability to handle high pressures and temperatures. In these boilers, water flows through tubes that are heated externally by combustion gases.

3. Fluidized Bed Boilers

Fluidized bed boilers are a modern and efficient type of boiler in thermal power plants. They use a fluidized bed of solid particles to improve combustion efficiency and reduce emissions.

4. Pulverized Coal-Fired Boilers

These boilers burn finely ground coal to achieve efficient combustion. They are a common type of boiler in power plants that rely on coal as the primary fuel source.

5. Waste Heat Recovery Boilers

These boilers utilize heat from waste gases generated during industrial processes, making them an energy-efficient choice for certain power plants.

Key Objectives of Boiler Water Treatment:

1. Prevention of Scaling

Scaling occurs when dissolved minerals in water precipitate and form deposits on boiler surfaces. These deposits act as insulators, reducing heat transfer and increasing energy consumption.

2. Control of Corrosion

Corrosion is caused by oxygen, carbon dioxide, or acidic substances in water. Proper treatment removes or neutralizes these elements, preventing damage to boiler tubes and other components.

3. Maintaining Steam Quality

High-quality steam is essential for efficient turbine operation. Water treatment ensures that impurities do not carry over into the steam, protecting turbines and reducing maintenance costs.

4. Reducing Blowdown Losses

Blowdown is the process of removing impurities from boiler water. Effective water treatment minimizes blowdown frequency, conserving water and energy.

The Role of Advanced Water Treatment Technologies

Modern water treatment technologies have transformed the way boiler systems are managed. These technologies include:

- Reverse Osmosis Systems: Effectively remove dissolved salts, reducing the risk of scaling.

- Electrodeionization (EDI): Produces high-purity water for high-pressure boilers.

- Membrane Filtration: Removes fine particles and microorganisms from feedwater.

- Automated Control Systems: Monitor and adjust water chemistry in real-time, ensuring optimal performance.

Comprehensive INDION Boiler Water Treatment by Ion Exchange

Ion Exchange provides a wide range of boiler water treatment programs for low-, medium-, and high-pressure boilers to prevent deposits and corrosion in pre-boiler, boiler, and post-boiler systems. Their unique DEHA-based oxygen scavengers offer superior protection against corrosion, even in condensate lines. Their boiler water treatment solutions include:

– Phosphate treatment program

– Carbonate treatment program

– Chelant program

– Closed system treatment

– Electric boiler treatment

– Sludge conditioners

– Anti-foamers

– Oxygen scavengers

Their complete condensate line treatment programs are designed to solve specific corrosion problems:

– Filming amines

– Neutralizing amines

– Combination of filming and neutralizing amines

These specialized programs ensure the efficiency and longevity of your boiler systems by addressing the distinct challenges faced in different stages of boiler operation. With their boiler treatment water solutions, they answer questions like what is boiler water treatment, what is boiler water treatment chemicals, what is the purpose of boiler water treatment, and which chemical is used in boiler water treatment.

Conclusion

Efficient water treatment is the cornerstone of reliable and cost-effective boiler operation in power plant systems. By preventing scaling, corrosion, and fouling, proper water treatment extends the lifespan of boilers and ensures consistent energy production. For different types of boilers in power plants, adopting advanced treatment technologies tailored to specific needs is essential to overcome challenges and meet operational demands.